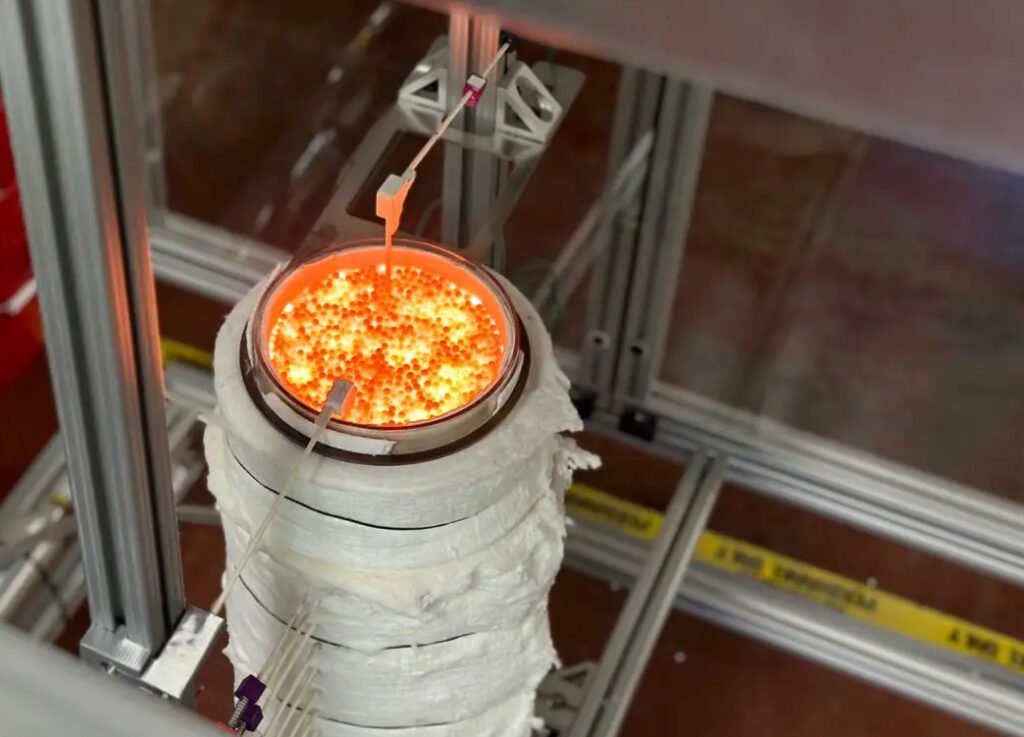

The US startup Furno Materials, headquartered in Mountain View, California, has successfully closed a $6.5 m seed funding round. The key innovation is their highly efficient, vertical reactor which reduces the 4-steps of clinker production into a single and compact stage. The calcination and sintering zone, which is more similar to a lime shaft kiln, can be adjusted, thermal efficiency shall be 88%. The feed material composition is like in conventional clinker production, but fully engineered with additives and ground to probably larger particle sizes. The modular reactor, when similar to lime shaft kilns with capacities of 50 to 600 tpd, could be interesting for concrete companies producing their own clinker and cement. However, not much information has been given, how the CO2 from the feed material decomposition will be captured to enable carbon-neutral cement.